| Model | HW-RC400 |

| Engine | Yuchai |

| Power | 110 KW |

| Max. Drilling Depth | 300 m |

| Drilling Diameter | 105~305 mm |

| Working Air Pressure | 1.2~3.5 MPa |

| Total Air Consumption | 16-55 m³/min |

| Drill Pipe Length | 3 m |

| Recommended Drill Pipe Diameter | Φ89/Φ102 mm |

| Recommended Dual-Wall Reverse Circulation Pipe | Φ89/Φ102 mm |

| Axial Pressure | 6 t (tonnes) |

| Lifting Force | 22 T (tonnes) |

| Slow Feed Speed | 20 m/min |

| Fast Feed Speed | 32 m/min |

| Max. Rotation Torque | 8000/4000 Nm |

| Max. Rotation Speed | 0-75 r/min; 0-150 r/min |

| Auxiliary Winch Capacity | 1.5 T (tonnes) |

| Leg Lifting Height | 1.6 m |

| Drilling Efficiency | 10-35 m/h |

| Traveling Speed | 2.5 Km/h |

| Gradability | 21° |

| Machine Weight | 11 t (tonnes) |

| Dimensions (L×W×H) | 6.2×1.85×2.8 m |

| Suitable Geology | Loose layers & bedrock |

| Drilling Method | Top-drive hydraulic rotation & feed, DTH hammer or mud drilling |

| Compatible Hammers | Medium/High air pressure series |

| Optional Accessories | Mud pump, centrifugal pump, generator, foam pump |

Features:

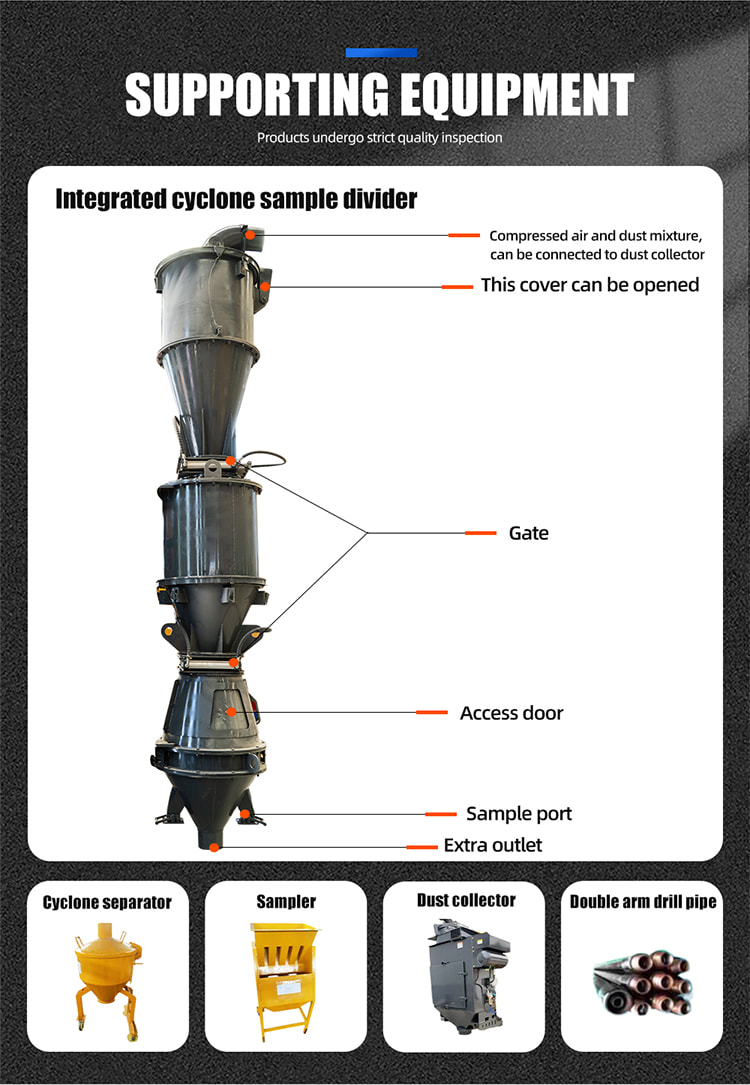

1. Dual-Pipe Reverse Circulation System: Utilizes an inner and outer pipe structure where air or foam is injected into the outer pipe to lift the rock cuttings through the inner pipe, improving drilling efficiency.

2. Efficient Cuttings Recovery: The reverse circulation method minimizes contamination of the rock cuttings, ensuring high-quality samples that are essential for mineral exploration.

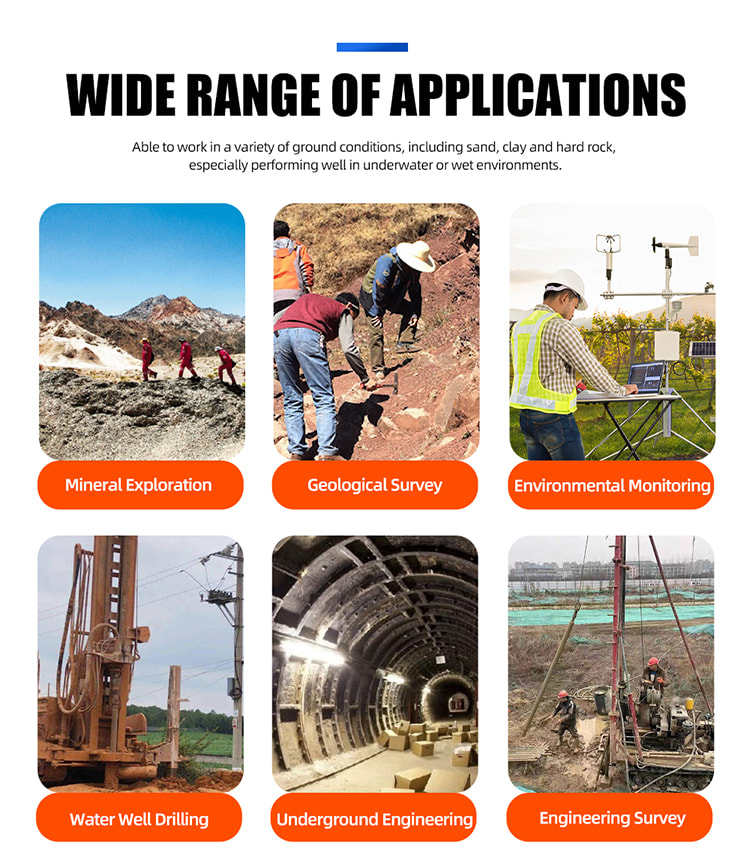

3. Strong Adaptability: Suitable for various strata, including loose soil layers, hard rock layers, and complex geological conditions.

4. Air-Driven Drilling: Uses compressed air as a power source, which reduces contamination of the formation compared to traditional mud drilling methods.

5. Fast Drilling Speed: The reverse circulation system enables rapid removal of cuttings, resulting in faster drilling speeds than conventional methods.

Advantages:

1. High-Quality Sample Recovery: Provides cleaner samples with no contamination from drilling fluids, making them more representative for exploration.

2. Eco-Friendly and Water-Saving: No need for large volumes of drilling mud, reducing environmental pollution, and especially useful in water-scarce regions.

3. Low Maintenance Costs: Compared to mud drilling systems, the equipment experiences less wear and tear, resulting in lower maintenance costs.

4. Reduced Risk of Hole Collapse: The reverse circulation system helps maintain a clean borehole, reducing the likelihood of borehole collapse.

5. Wide Application Range: Suitable for not only mineral exploration but also water well drilling, geothermal wells, and other engineering applications.

Shandong Hengwang Group Co., Ltd., as one of the top drilling machinery and piling machinery suppliers in China, has 20 years of experience in the production of drilling rigs and piling machines.

Fill in the form to get the latest product parameters and the lowest price.

Simply complete the form below and a Hengwang product expert will contact you shortly.